Medical devices We design to help

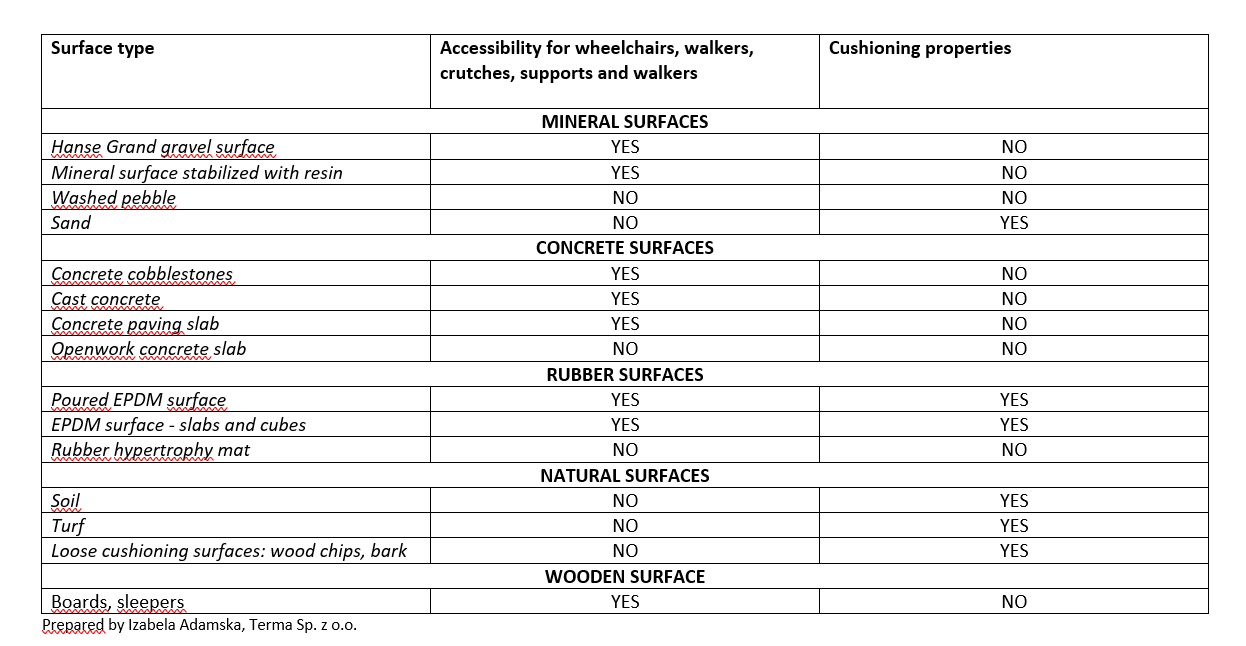

How to choose the right surface for an inclusive playground?

Surfaces must be accessible to able-bodied people, but also those using a wheelchair, crutches, as well as walkers and supports. Equipping a playground adapted to the diverse needs of the device makes no sense at all when the material used as a surface will completely prevent access to them.

Communication routes and the surroundings of playground equipment, apart from aesthetic values, should also have an appropriate form and function, and comply with the PN-EN 1176 standard, which regulates, among others, issues of adequate amortization of possible falls on playgrounds.

EN 1176 standard

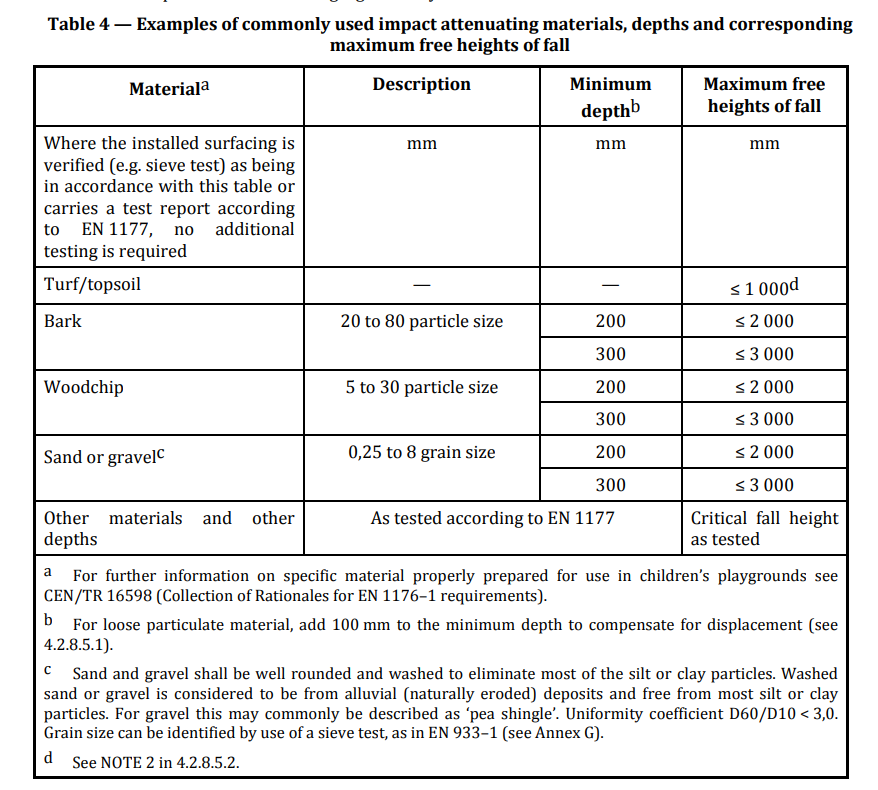

Surfaces on the playground, especially those around the devices, must ensure convenient access, but also, above all, the safety of users. In accordance with the EN 1176 standard, all play equipment with a free fall height greater than 600 mm and/or devices that force the user to move (e.g. swings, slides, rocking devices, roundabouts, etc.) on the impact-dampening surface over the entire impact area.

source: EN 1176

Accessibility standards

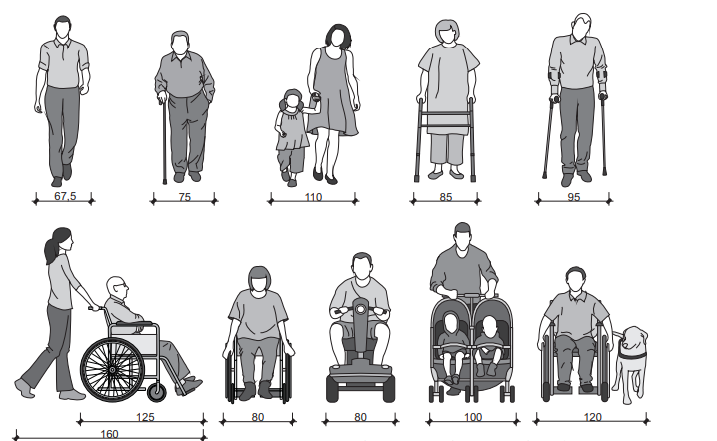

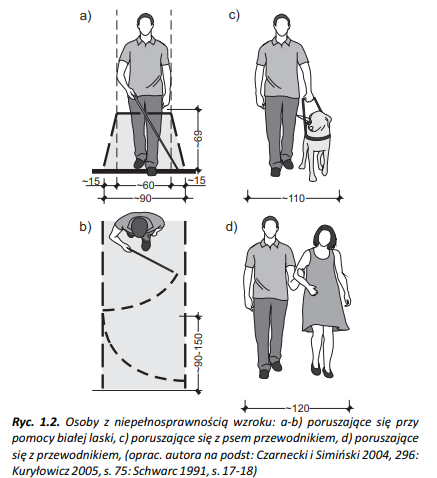

A situation in which a person with disabilities is denied access to play on the playground due to architectural and communication barriers is unacceptable. It is worth remembering that disability does not mean only a situation in which a person moves in a wheelchair. Special needs regarding the surface also apply to people using crutches, walkers and supports, as well as rehabilitation walkers. People with visual disabilities also need additional facilities. Accessibility standards adopted by individual cities take into account the needs of people with various types of disabilities, in particular people with physical disabilities, blind and visually impaired people, hearing disabilities, intellectual disabilities, mental disorders or diseases, and communication difficulties.

What dimensions?

The minimum width of paths in the playground should be 150 cm. The main pedestrian routes should be designed with a width of min. 200 cm, which allows two wheelchairs to easily pass each other. Hardened approaches must be used for devices intended for people in wheelchairs, in accordance with fall absorption requirements. Pavements in inclusive areas should also include the necessary space for maneuvering, as well as a rest area, including access to benches and tables. More information on the correct dimensions and design of the zone around the benches can be found in the article at the following link: https://www.termamed.pl/pl/opinions/jak-projektowac-teren-obok-lawek-dos.... A great facilitation when maneuvering a wheelchair and a pram in places where communication routes cross is designing the surface in such a way that instead of right angles, in places of change of direction, there are arches with a radius of 100 mm covered with the surface. They guarantee a comfortable and safe journey. Otherwise, in the case of pavements made in a standard way, it is very easy to drive the wheelchair wheel beyond the range of the pavement when turning. The surfaces should connect with each other in a non-threshold manner (curbless, or the curb should be flush with the surface) so as not to create barriers for users. The transverse inclination of the pedestrian route should not exceed 3.0% (Regulation of the MTiGM 1999), and the longitudinal 5%. Too high transverse inclination of the pedestrian route makes it difficult for people in wheelchairs to move around, and it is difficult for the blind to maintain a straight line of walking with a large inclination of the pedestrian route. An important issue is the fact that the accessibility of the surface must be ensured regardless of weather conditions, e.g. also after rain.

źródło: Standardy dostępności Miasta Gdynia, autor opracowania dr hab. arch. inż. Marek Wysocki

The choice of the surface is often an attempt to compromise between issues related to functionality, safety, as well as the costs of implementation and maintenance in subsequent years. In the case of a limited budget, the choice falls most often on sand or lawn, but this is a situation that completely contradicts accessibility on the playground, because such a surface is a barrier for wheelchairs and people moving with the help of a walker, walker or support. It is also difficult for prams to move on it, which in such a situation, after removing the child, are often left unattended on pedestrian routes, posing a threat to people moving along the communication route. Choosing the right surface should therefore always be a choice that results from the analysis of many criteria and the needs of future users. It is also worth remembering that, just like zonal design of playgrounds, when looking for a compromise in the context of surfaces, it is worth trying to combine them skillfully to ensure accessibility, safety, stylistic coherence and cost optimization of performance.

MINERAL SURFACES

Hanse Grand gravel surface

The great advantage of Hanse Grand and Hanse Grand surfaces is the fact that they harmoniously blend into the natural environment, so they are perfect as a material for paths in parks and playground surroundings, especially with a large number of plantings. The surfaces are made of high-mountain slate, special binding gravel and natural stone, so it is permeable to rainwater. It is an alternative to concrete or asphalt surfaces. It can be successfully used instead of or next to paving stones. It is also accessible to people with disabilities and wheelchair friendly. Boules courts are often made of this surface. It does not have fall-absorbing properties, so it cannot be used around playground equipment for which such amortization is required. Hanse Grand surfaces are included in the designs as biologically active surfaces.

Mineral surface stabilized with resin

Their great advantage, both in terms of utility and biological, is the ability to pass rainwater and soak it into the ground, which prevents the accumulation of water on the surface of the path in the form of puddles. In addition, mineral surfaces are resistant to various weather conditions, including frost and UV radiation. They are also highly abrasion resistant. They do not crumble and do not dust, thanks to which they are non-staining material. Depending on the mineral aggregate used, they can come in different colors and textures. Colored versions are also available, allowing you to bring color to the playground, which not only increases the level of attraction for children, but can also help mark out zones. Mineral pavements stabilized with resin, despite their ability to pass water, are not considered as biologically active surfaces, so they do not increase its sum in the design. They also do not have fall-absorbing properties, so they cannot be used around devices for which such amortization is required.

Washed pebble

Pebbles are not suitable as a surface material, especially for people with special needs. First of all, it is impossible to stabilize such a surface, because the stones have smooth edges, so there is no effect of their wedging against each other and permanent stabilization. As a result, such a surface is not suitable for people with mobility problems, as well as those using wheelchairs. It is also a surface that is also not the best choice for standard prams, as well as for seniors. Despite the relatively low cost of setting up such a surface, it requires a lot of money to maintain such a surface and, due to safety and maintenance issues, it is recommended rather for private gardens than playgrounds and their surroundings.

Sand

The most common surface used in playgrounds is sand. Unfortunately, this solution is only suitable for able-bodied people or those who do not have mobility problems. Therefore, it cannot be used on the entire surface of an inclusive playground. Sand has good shock-absorbing properties, so it can be used (depending on the thickness of the layer and the height of the free fall) as a shock-absorbing surface for higher devices, where the free fall height is less than or equal to 2 m for a layer of 20 cm and less than or equal to 3 m for 30 cm layer. Playgrounds sprinkled with sand in their entirety or around devices that are even adapted to the needs of people with disabilities are completely inaccessible to these people.

CONCRETE SURFACES

Concrete cobblestones

Cobblestones are a good solution in the context of communication routes on the playground and the surroundings of devices that do not require a shock-absorbing surface. Choosing the right cube should take into account the needs of people in wheelchairs, so the so-called old pavements and products that require a wider joint. Any such unevenness means difficulties in reaching the playground not only for people in wheelchairs, but also for seniors using crutches, whose caps can get stuck in the unevenness. Concrete cubes give a lot of design possibilities in terms of color selection, as well as marking zones and lines leading through the playground. It also allows for the installation of additional horizontal markings for people with visual disabilities, as well as the adaptation of small slopes of the terrain without the need to level them to level 0. It is also relatively durable and cheap to maintain.

Source: Switch, Integracja Foundation.

Cast concrete

Concrete used on playgrounds is a material that allows for free shaping of pedestrian routes and ensuring a smooth surface. It can be in a natural color and dyed in several colors. Colored concretes can be used in the same areas as standard concretes: sidewalks, bicycle paths, driveways. They are a very durable material; they do not require maintenance and corrections, as is the case with paving stones. Concrete surfaces are resistant to deformation or grass growth. However, the execution of such a surface may only apply to communication routes, ramps or the surroundings of devices that do not have a free fall height, because concrete is not a shock-absorbing surface. When it comes to accessibility for people with different levels of fitness, if the surface has been made correctly, it does not crack over time under the influence of overgrowing tree roots, it is a very comfortable surface for people with limited mobility. In green areas and playgrounds, concrete is also used, which, unlike ordinary concrete, has the ability to freely and quickly drain rainwater from the surface to deeper layers. The main characteristic of permeable concrete is a network of connected voids, the volume of which should normally be between 15% and 30%. Since the material's properties allow rainwater to infiltrate the surface areas and the permeable layers below, it is necessary to control the surface and regularly wash the surface, and at least twice a year to perform a comprehensive cleaning, before and after the winter period. Cavity concrete can also be used as a base for EPDM or other surfaces used on playgrounds. In itself, it is not a surface that absorbs falls, so it cannot be installed in the so-called safety zones that require such a surface in accordance with EN 1176.

Concrete paving slab

Surfaces made of concrete paving slabs are cheaper than cast concrete, but less durable and susceptible to surface deformation. When it comes to people with limited mobility, the greatest threat to them is any unevenness and unexpected losses, as well as warping of the plates relative to each other. Such a surface should also not have wide joints, and preferably the top layer of the boards has the texture of small pebbles, which gives an anti-slip effect. A concrete slab is recommended rather for lining small spaces, such as a recreation area, the area under benches, around table devices, using a curb or concreting the edges to keep the slabs in a compact structure. Such a surface requires regular inspections by the administrator and repair of any defects, because it can quickly pose a threat and prevent the use of the space by people with limited mobility. A concrete slab, like other concrete products, is not a fall-absorbing surface, so it cannot be installed in the so-called safety zones that require such a surface in accordance with PN-EN 1176.

Openwork concrete slab

Openwork concrete slabs are a tempting solution when the project lacks a total biologically active surface. The openwork slab is potentially an ideal solution - it is water-permeable and allows plants to germinate in free spaces. Unfortunately, such a surface is unavailable for people in wheelchairs, crutches, walkers, walkers and props. It is also not comfortable for prams and dangerous for seniors. The wheels of the aids, as well as the caps of the balls and supports, can easily get stuck in the free spaces of the boards. Another threat is the fact that overgrowing grass and other plant species, not maintained and mowed regularly, will make it practically impossible for people with disabilities to drive or walk on it. Concrete openwork slabs are therefore not a recommended surface for inclusive places.

RUBBER SURFACES

Poured EPDM surface

The great advantage of cast EPDM is the possibility of designing the surface in any shape and in multicolored colors, allowing for marking subsequent zones and the logic of the playground. It allows you to adjust the safe and functional space of the playground and full access for people with disabilities. It is an ideal solution for hills, hills and other three-dimensional elements. It has shock-absorbing properties, so it can be used in the safety zones of devices with a certain height of free fall. The poured EPDM surface consists of two layers. The first is a base mat made of SBR granules and polyurethane with a thickness adapted to the installed play equipment and the critical fall height (HIC coefficient). The second one is the wear layer, made of colored EPDM granules (1-3 mm) with a thickness of 8-10 mm, depending on the needs of depreciation. The disadvantage of the rubber surface is the impermeability of rainwater and the perceived increased temperature during sunny days reported by users, as well as in some cases the perceptible smell of rubber, reducing comfort when spending time on the playground. The rubber surface is also relatively expensive and requires several layers to be resistant to weather conditions and meet the depreciation condition.

EPDM surface - slabs and cubes

The EPDM shock-absorbing surface in the form of plates or cubes is an alternative to the poured version, but due to the specific shape of the plates and cubes, it gives less possibilities to form any shapes. In the case of EPDM slabs and cubes, it is very important to install them correctly, otherwise the slabs will start to float and warp relative to each other. Such a surface not only becomes inaccessible to people with mobility limitations, but also uncomfortable for able-bodied children and carers who may trip over the raised slabs and fall over. The condition for accessibility is therefore careful assembly and good quality products as well as a properly made foundation. The disadvantage of the rubber surface is the impermeability of rainwater and the perceived increased temperature during sunny days reported by users, as well as in some cases the perceptible smell of rubber, reducing comfort when spending time on the playground.

Rubber hypertrophy mat

Overgrowth mats, like openwork concrete slabs, are water-permeable and allow plants to germinate in free spaces, so they are a biologically active surface. Unfortunately, such a surface is unavailable for people in wheelchairs, crutches, walkers, walkers and props. It is also not comfortable for prams and dangerous for seniors. The wheels of the aids, as well as the caps of the balls and supports, can easily get stuck in the free spaces of the boards. Another threat is the fact that overgrowing grass and other plant species, not maintained and mowed regularly, will make it practically impossible for people with disabilities to drive or walk on it. Hypertrophic mats are therefore not a surface recommended for inclusive areas.

NATURAL SURFACES

Soil

Leaving the playground surface bare is a very popular solution, especially on community playgrounds. Often the soil present as a surface is a by-product of a once-existing lawn that has been trampled down. Interestingly, this solution is not the worst in terms of amortization of falls - the PN-EN 1176 standard allows the use of soil as a cushioning layer for a fall height of up to 1 m. in wheelchairs, on crutches, with walkers, walkers and supports. Puddles form on it, and it is easy to get stuck in unevenness. Therefore, a person with a disability will need the help of carers to move on such a surface.

Turf

Just like soil, the use of a grass surface as the top shock-absorbing layer is acceptable for a fall height of up to 1 m. It is also a cheap solution and probably the most popular on playgrounds. Unfortunately, the biggest problem is neglect in the care of lawns on playgrounds and their rapid trampling. It is also a surface on which wheelchairs are not able to pass, or a disabled person requires constant assistance of a guardian to move within the playground or to reach it at all. Therefore, from the point of view of accessibility, the lawn cannot be considered as an accessible surface that can be used in inclusive playgrounds.

Loose impact attenuating surfaces: wood chips, bark

According to the PN-EN 1176 standard, wood chips and bark have good shock-absorbing properties. They can therefore be used around devices that require fall absorption. With a layer of 20 cm, it is depreciation for a height of up to 2 m and with a layer of 30 cm, up to 3 m. Unfortunately, neither chips nor bark are a material on which a person with physical disabilities will be able to move - neither in a wheelchair nor in a wheelchair. on a walker, walker or on crutches. Also for the elderly, loose and soft surface is difficult to overcome and dangerous, so it can contribute to a fall.

WOODEN SURFACE

Wood is a very friendly material, especially in natural playgrounds. It is also used as a material from which surfaces are made in the form of platforms leading to individual devices or for moving between, for example, an activity zone on a playground and a rest or landscape zone. As for the properties of wood in terms of accessibility for people with limited mobility, it has good parameters and fits beautifully with the plants surrounding the playground. However, the condition is to lay the boards with gaps of max. width 5 mm. Unfortunately, the greatest threat for people with disabilities is when the wood is wet - as a result of rainfall, high air humidity, and also when the water freezes. The surface in such a situation becomes slippery and very dangerous. A common mistake that is made when designing wooden surfaces leading to individual devices is the fact that they are not provided around the entire device, but only in its vicinity. This is due to the requirement of the PN-EN 1176 standard, because wood does not absorb falls and therefore cannot be used directly around the device, which has a safety zone requiring adequate cushioning. In such a situation, the user with a disability is isolated on the platform, because there is no possibility of sliding down or descending from it (usually a height of 20-40 cm), because there is sand, bark or wood chips below. Parents do the same, leaving prams on the platforms and descending with children to the devices. Abandoned wheelchairs prevent safe passage/crossing and pose a threat to people using this communication route. This situation is simply a design error in the face of the need to reconcile the concept with the norm for playgrounds. In a situation where the device requires a shock-absorbing surface, instead of insulation and segregation of users, a different surface should be designed around these devices (e.g. EPDM), which absorbs falls and gives access to the devices also for people with disabilities. Wood can be used as a surface around devices that do not require depreciation and thus allow access for all users, regardless of their level of fitness.