Medical devices We design to help

Results of neglecting the inspections on the playground

Checking the technical condition of the devices is extremely important because efficient, complete and controlled play devices allow the child to be safe.

.

The risk on the playground is an integral part of the play, however, in accordance with EN 1176, the risk must be foreseeable by the child. The aim of playgrounds is therefore to provide opportunities for play with an acceptable risk. Play with a certain degree of risk is desirable because it gives children the opportunity to recognize these risks and draw conclusions in a controlled environment. The playground is therefore a place of controlled play that ensures the child's safety, but also the opportunity to explore the world, learn to cooperate and compete, and experience stimuli influencing the proper sensory development.

The purpose of the EN 1176 standard is not to eliminate the risk altogether, but to make the risk acceptable and not result in accidents, unfortunate events or significant damage to health

Checking the technical condition of the devices is extremely important because efficient, complete play devices allow the child to be safe and predict the consequences. In a situation where, for example, in the ladder on which the child is climbing, one of the rungs is movable and the child finds this fact only when entering it, it means that the administrator did not fulfill his obligations properly.

Routine inspection

The purpose of the inspection is to reveal obvious hazards that may result from normal use, vandalism or weather conditions. Routine inspection should take place every 1-7 days. In intensively used playgrounds or those exposed to vandalism, it should be held every day. This inspection may be carried out by a person maintaining order and cleanliness (no special qualifications are required).

Functional inspection

This is a kind of more careful inspection than a routine one. Its purpose is to check the operation and stability of devices. Typical functional checks include a wear test and should be performed every 1-3 months or as recommended by the equipment manufacturer. During the inspection, it is recommended to pay attention to the functionality of the device, as well as its parts (including those that cannot be dismantled) and stability (especially important for devices whose stability depends on one column).

The following schedule for performing functional checks is recommended:

• after winter - to check the condition of devices before the season. Instead of this control, the annual control - the main one,

• summer inspection - it is about safety assessment before the holiday season, when the use may be more intensive,

• post-vacation inspection - in order to note any possible damage or defects resulting from intensive use,

• autumn inspection - at the end of the playground use season.

Annual inspection

The annual inspection is performed to establish the general level of safety of playground equipment, foundations and surfaces. It is recommended to carry out an annual inspection before the season of use, i.e. after winter. It can replace one of the functional controls.

Typical checks include the effects of the weather, rotting, corrosion and any changes to the safety of the equipment.

The test covers the stability of devices and the condition of underground parts (foundations) that may be excavated, their stability damaged or destroyed. The foundations of the equipment as well as the surface on the playground are analyzed. The impact of moisture from groundwater or water stagnating temporarily on the playground should be assessed. Compliance with post-inspection recommendations from previous inspections and the current standard of maintenance of the playground should be assessed.

Responsibilities of the playground administrator

In the context of inspections, the administrator's responsibility is to establish a schedule for inspections of each playground that is subject to him and to determine who is to perform these inspections. The schedule is determined on the basis of the recommendations of the device manufacturers, as well as the real risk, i.e. the intensity of use of a given playground or its exposure to vandalism.

A book of inspections and controls should also be established for each playground. A schedule with specific inspection dates must appear in the ledger.

As an appendix to the book, the administrator should have operating instructions containing recommendations for inspection and maintenance for each device that is part of the playground.

Unfortunately, in many places administrators still do not have inspection and control records and these checks are not performed regularly.

Failure to perform regular inspections contributes to the deteriorating technical condition, and thus lowering the level of user safety. In the event of an accident on the playground, the administrator's lack of care for the condition of the facility may be the direct cause of it!

We encourage you to download the pattern prepared by us, and if you have any questions, contact our sales managers.

Anna Michułka

Manager

Sales – Medical Products

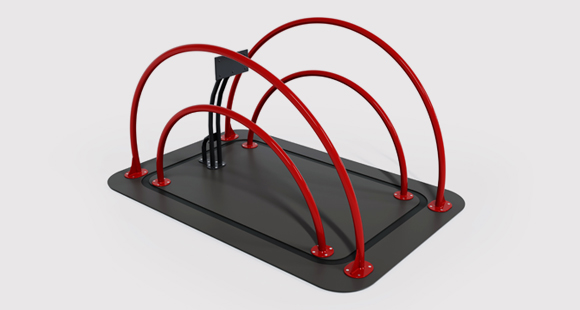

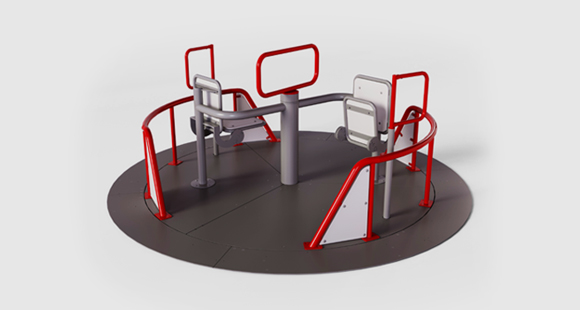

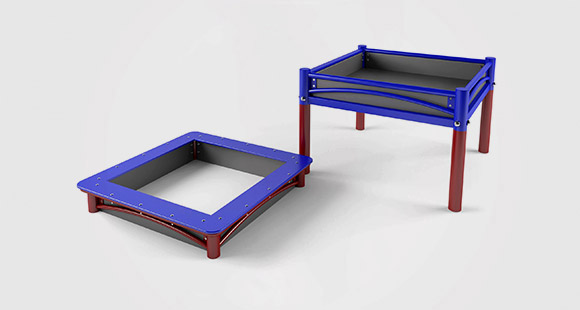

Rehabilitation devices, Inclusive playground equipment

Poland, South, Export

M: +48 / 607 467 981

anna.michulka@termagroup.pl

Mariusz Sankowski

Manager

Sales – Medical Products

Rehabilitation devices, Inclusive playground equipment

Poland, North

M: +48 / 609 900 451

mariusz.sankowski@termagroup.pl